Striking Efficiency: Manufacturing Rappers for Reliable Rapping Systems in Energy-from-Waste Plants

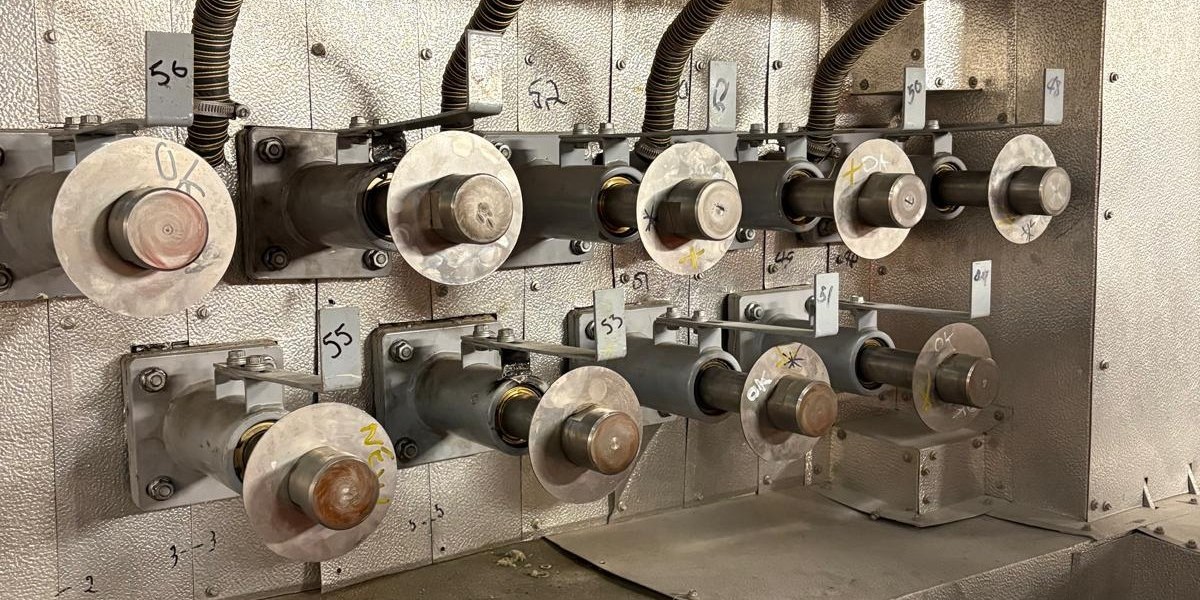

In the world of Energy-from-Waste (EfW), reliability is everything. To ensure optimal performance of electrostatic precipitators (ESPs) and other emission control systems, rapping systems play a vital role. At the heart of these systems are “rappers” – precision-engineered components responsible for keeping surfaces clean and operational through mechanical impact. At first glance, they might seem simple. In practice, they’re anything but.

What Is a Rapping System?

A rapping system is designed to remove particulates from surfaces inside an ESP by delivering a controlled impact — or “rap” — to the collection plates and discharge electrodes. This process dislodges ash and dust, allowing it to fall into hoppers below for safe removal. Without effective rapping, particulate build-up would reduce the efficiency of the ESP and potentially breach emission limits.

Why the Quality of Rappers Matters

In Energy-from-Waste plants, reliability and uptime are essential. Rappers must operate in harsh, high-temperature environments and deliver consistent impact over millions of cycles. That means the quality of their design, materials, and manufacture directly impacts plant performance.

A poorly manufactured rapper can lead to uneven rapping, mechanical failure, or premature wear – all of which can result in reduced particulate collection efficiency or costly unscheduled maintenance. In contrast, well-designed and precisely manufactured rappers ensure that rapping forces are consistent, effective, and long-lasting.

Manufacturing for Precision and Durability

At IME Contracts, we specialise in the UK-based manufacture of mechanical and electromagnetic rappers, ensuring each unit is built to withstand the rigours of EfW operations. Our process includes:

-

Material selection for high-temperature resistance and mechanical strength

-

Precision machining to ensure dimensional accuracy and consistent striking force

-

Rigorous testing for durability, impact energy, and operational reliability

-

Custom builds to suit both OEM and retrofit applications

This approach ensures minimal variation between strikes, optimising dust dislodgement without damaging the ESP internals.

Retrofitting & Replacement Rappers

Whether you're facing end-of-life components or looking to improve existing systems, IME provides like-for-like rapper replacements and bespoke retrofitting services for all major ESP systems. Our rappers are compatible with popular models from OEMs such as Lodge Cottrell, FLSmidth, and others — allowing for quick integration without compromising performance.

Supporting UK Sustainability Goals

EfW plays a key role in the UK’s transition to a circular economy, and efficient emission control is non-negotiable. By ensuring your rapping systems are supported by reliable, UK-manufactured rappers, you not only extend the life of your equipment but also maintain compliance and efficiency with minimal disruption.

Looking to strike the right balance between performance and reliability?

Get in touch with our engineering team today to learn more about our manufacturing capabilities and how we support EfW plants across the UK and Europe. For specialist advice and a no-obligation quotation, call IME on 02085996570 or email sales@imegroup.co.uk.