Precision in Motion: Harnessing Horizontal Boring Machines for Manual Machining In London

The Power of Precision Engineering

In the heart of London’s bustling manufacturing industry, precision engineering is a key driver of success. Among the various machining techniques available, horizontal boring machines (HBMs) have become indispensable for manual machining applications. These machines provide exceptional accuracy, stability, and efficiency—essential for industries ranging from aerospace and automotive to construction and energy.

What is a Horizontal Boring Machine?

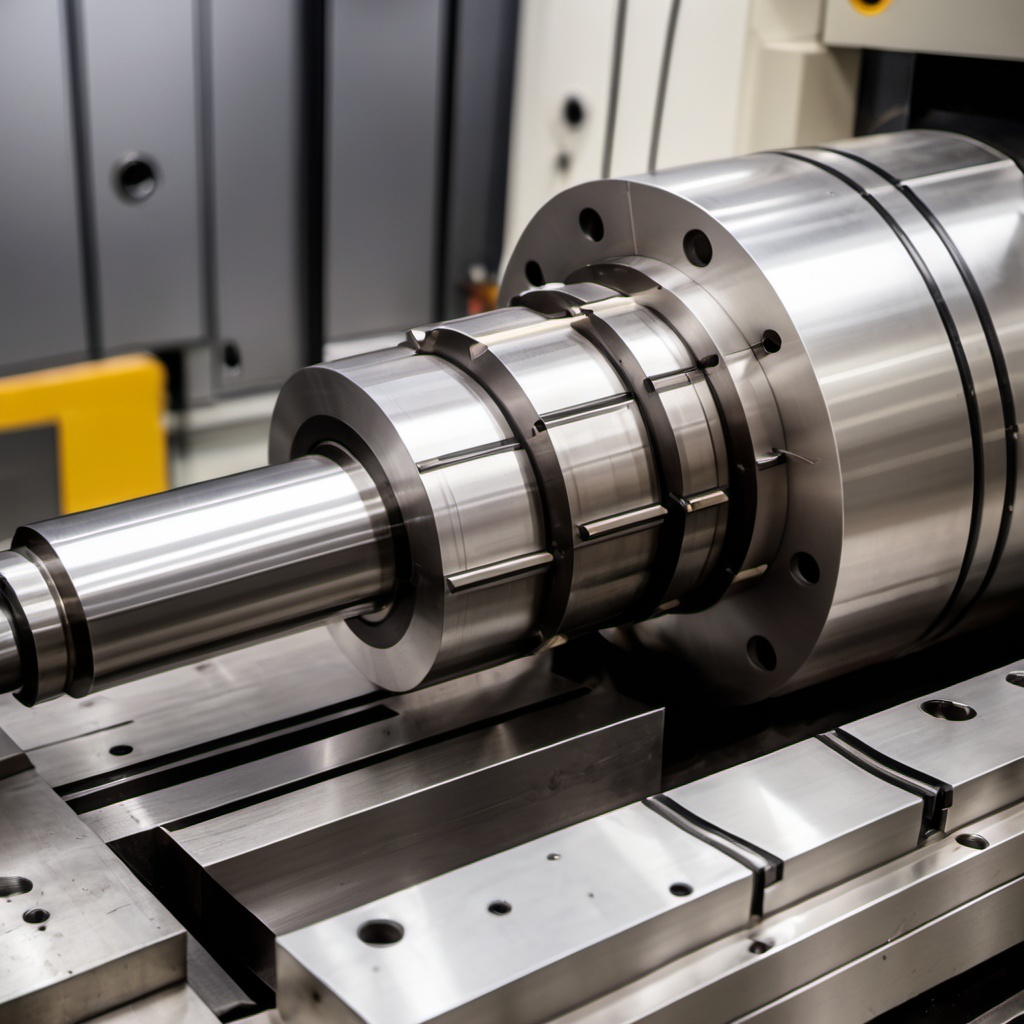

A horizontal boring machine is a type of machining tool designed to enlarge existing holes or create precise bores in large workpieces. Unlike vertical boring machines, which drill downward, HBMs operate along a horizontal axis, allowing machinists to work on heavy, bulky, or irregularly shaped components with greater ease.

In manual machining, skilled operators control the machine by adjusting cutting speeds, tool positions, and feed rates to achieve unparalleled accuracy. This hands-on approach ensures that every component meets strict specifications, making HBMs a crucial asset in industries where even the smallest error can lead to costly setbacks.

Why Use Horizontal Boring Machines for Manual Machining?

London’s manufacturing sector thrives on efficiency and precision. Here’s why horizontal boring machines play a pivotal role:

✅ High Accuracy – HBMs deliver tight tolerances, ensuring perfect alignment and consistency in machined parts.

✅ Versatility – From steel components to engine blocks, HBMs can handle a wide range of materials and sizes.

✅ Efficiency in Large-Scale Machining – They enable precise machining of large and heavy workpieces that would be difficult to manage using other equipment.

✅ Customisation & Manual Control – Skilled machinists can make real-time adjustments, allowing for greater flexibility in custom machining projects.

Applications of Horizontal Boring Machines in London

As a hub of precision manufacturing, London is home to businesses that rely on HBMs for various applications, including:

- Aerospace Manufacturing – Ensuring tight tolerances for aircraft components.

- Oil & Gas Industry – Machining precision bores in heavy equipment.

- Automotive & Rail Engineering – Creating accurate holes for axles, frames, and other vehicle parts.

- Construction & Structural Engineering – Producing large-scale metal components for bridges and buildings.

The Future of Manual Machining in London

Despite the rise of automation and CNC machining, manual machining with horizontal boring machines remains vital in many industries. The expertise of skilled machinists ensures a level of craftsmanship and adaptability that automated systems cannot always replicate.

With ongoing advancements in tooling, digital measurement techniques, and hybrid machining solutions, London’s engineering sector is set to thrive, blending traditional manual expertise with cutting-edge technology.

Conclusion

Horizontal boring machines are more than just tools—they are the backbone of precision machining in London. Whether it’s aerospace, automotive, or heavy engineering, businesses continue to rely on manual machining for accuracy, flexibility, and efficiency.

For those seeking high-quality manual machining services in London, investing in the right machinery and skilled professionals is the key to success.