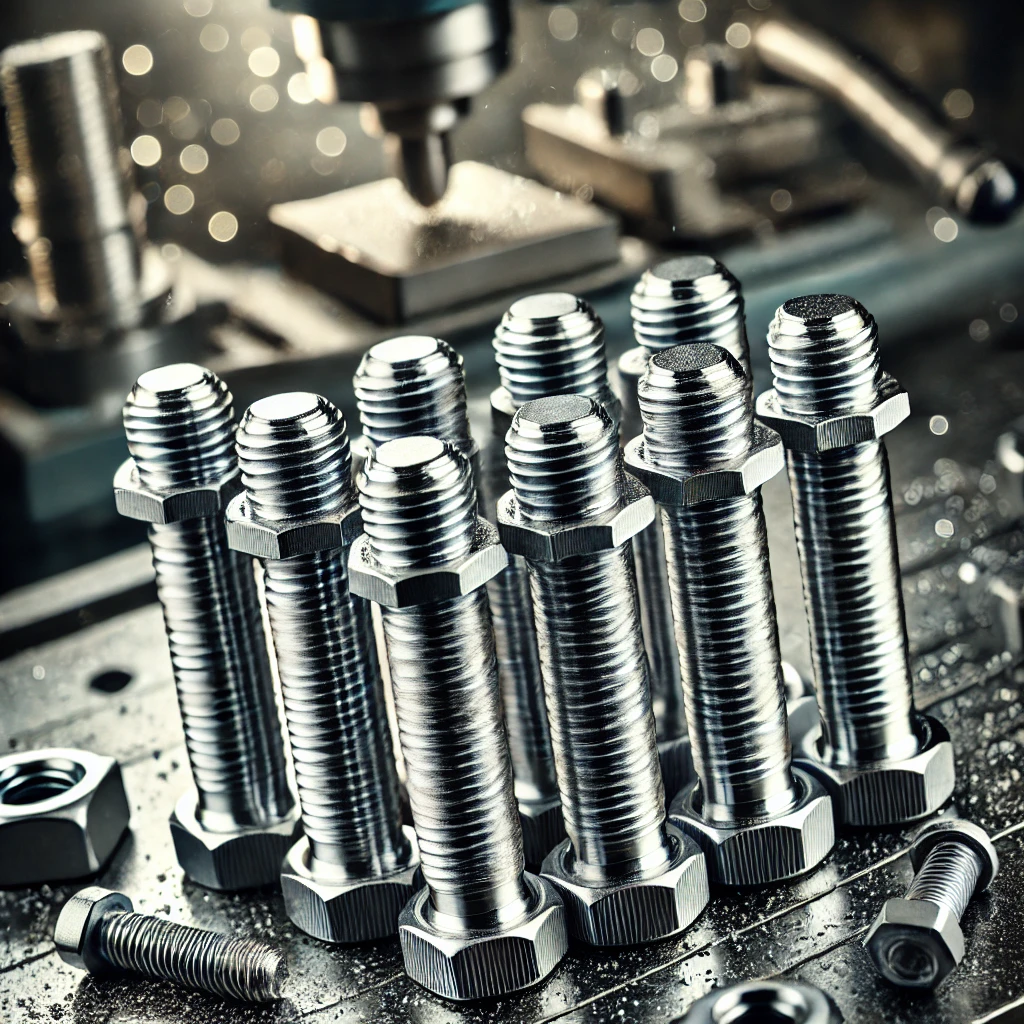

Precision Engineering: The Art of Manual Machining Stainless Steel Stud Bolts

In the world of precision engineering, the manual machining of stainless steel stud bolts stands out as both a science and an art. These small but mighty components play a crucial role across numerous industries, from construction to petrochemicals, ensuring structural integrity and operational safety. This blog delves into the intricate process of creating stud bolts through manual machining, highlighting the skill, precision, and dedication required to achieve excellence.

The Importance of Stainless Steel Stud Bolts

Stainless steel stud bolts are integral to many industrial applications due to their strength, durability, and resistance to corrosion. Unlike standard bolts, stud bolts are threaded at both ends, making them ideal for high-pressure environments where a secure and reliable fastener is essential. Whether used in assembling heavy machinery or holding flanges together in pipeline systems, the quality of these components can mean the difference between seamless operation and costly downtime.

Challenges of Machining Stainless Steel

Stainless steel is prized for its unique properties, but these same traits make it notoriously difficult to machine. Its high strength and hardness, coupled with low thermal conductivity, create challenges such as:

-

Tool Wear: The toughness of stainless steel accelerates wear on cutting tools.

-

Heat Generation: Poor heat dissipation can lead to overheating, causing tool damage or material distortion.

-

Work Hardening: Stainless steel tends to harden under machining pressure, making it even harder to cut as the process progresses.

Overcoming these challenges requires not only advanced tools but also the expertise of a skilled machinist.

The Art of Manual Machining

Despite advancements in CNC (Computer Numerical Control) machining, manual machining remains a cornerstone of precision engineering. The manual approach offers unparalleled control and flexibility, especially for custom or small-batch projects where attention to detail is paramount. Here’s how machinists transform raw stainless steel into precision-engineered stud bolts:

-

Material Selection:

-

Machining starts with selecting the appropriate grade of stainless steel. Popular grades like 304 and 316 offer excellent corrosion resistance and strength, with 316 being the preferred choice for marine and chemical environments.

-

-

Preparation and Cutting:

-

The stainless steel bar stock is cut to the desired length using a bandsaw or lathe. Accurate measurement at this stage ensures the final bolt meets exact specifications.

-

-

Threading:

-

Threads are carefully cut at both ends using a threading die or a lathe equipped with threading tools. Precision is critical here, as even the slightest deviation can compromise the bolt’s performance.

-

-

Surface Finishing:

-

To achieve a smooth surface and remove machining marks, the bolt undergoes polishing and deburring. This step not only enhances aesthetics but also prevents corrosion hotspots.

-

-

Quality Control:

-

Each bolt is meticulously inspected for dimensional accuracy, thread conformity, and surface finish. Tools such as micrometers, thread gauges, and calipers are used to verify tolerances.

-

Why Manual Machining Matters

While automated systems excel at mass production, manual machining brings a level of craftsmanship that cannot be replicated by machines. Experienced machinists rely on their knowledge, intuition, and steady hands to produce components that meet exacting standards. Their ability to make real-time adjustments and troubleshoot issues on the fly ensures that even the most complex or bespoke designs are executed flawlessly.

Applications of Stainless Steel Stud Bolts

The versatility of stainless steel stud bolts makes them indispensable in numerous sectors:

-

Oil and Gas: Used in flanged connections in high-pressure pipelines.

-

Construction: Provides reliable fastening for structural steel components.

-

Marine: Resistant to saltwater corrosion, ideal for shipbuilding and offshore installations.

-

Power Plants: Withstands extreme temperatures and pressures in energy generation systems.

The Future of Precision Engineering

As industries demand higher standards of performance and reliability, the role of precision engineering continues to evolve. Advances in materials, tools, and techniques are enhancing the efficiency and accuracy of machining processes. However, the artistry and expertise of manual machining remain irreplaceable, especially when creating high-quality components like stainless steel stud bolts.

Conclusion

Precision engineering is more than just a technical process; it’s an art form that requires skill, patience, and dedication. The manual machining of stainless steel stud bolts exemplifies this perfectly, showcasing the craftsmanship that ensures these vital components perform flawlessly in demanding environments. By valuing and supporting skilled machinists, we can continue to uphold the highest standards of engineering excellence.

Whether it’s securing a pipeline or withstanding the harshest marine conditions, stainless steel stud bolts are a testament to the power of precision engineering—crafted by hand, designed to last. For specialist advice and a no-obligation quotation, call IME on 02085996570 or email sales@imegroup.co.uk.