Seamless Solutions: Mastering Stainless Pipework Installations in London

London, a city synonymous with innovation and excellence, is home to a myriad of industries that rely heavily on precise and durable infrastructure. One critical aspect of this infrastructure is stainless pipework, which plays a vital role in sectors ranging from healthcare to hospitality. In this blog, we explore the art and science of mastering stainless pipework installations in London, delving into its importance, applications, and the expertise required to achieve seamless solutions.

The Importance of Stainless Pipework

Stainless steel pipework is prized for its corrosion resistance, durability, and aesthetic appeal. These qualities make it an ideal choice for a variety of applications, including:

-

Healthcare Facilities: Hospitals and medical centers require piping systems that can withstand rigorous cleaning protocols and resist contamination. Stainless steel’s hygienic properties make it the material of choice for these environments.

-

Food and Beverage Industry: In food processing plants, breweries, and commercial kitchens, stainless steel pipework ensures that products remain uncontaminated and meet strict health standards. Its ease of cleaning and resistance to corrosion are essential for maintaining hygiene.

-

Construction and Architecture: Stainless steel is used in building services for water supply, heating, and cooling systems. Its sleek, modern appearance also makes it a popular choice for architectural features and exposed pipework in contemporary designs.

-

Pharmaceutical Industry: The production of pharmaceuticals demands an ultra-clean environment. Stainless steel piping ensures the purity of water and other fluids used in the manufacturing process, preventing contamination.

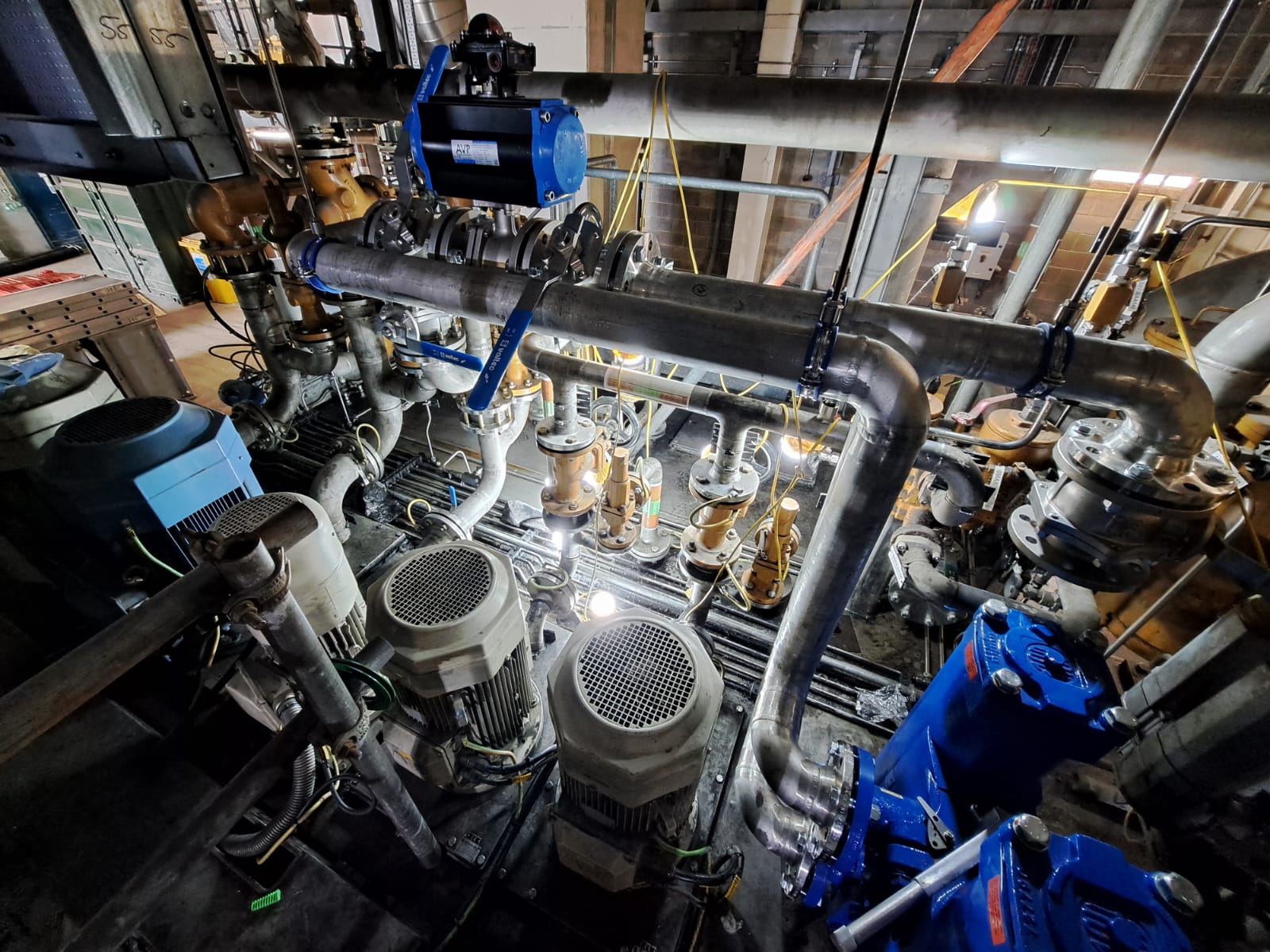

Techniques and Technologies in Stainless Pipework Installation

Achieving seamless stainless pipework installations requires a blend of traditional craftsmanship and modern technology. Here are some key techniques and technologies employed in London:

-

Welding and Fabrication: Precision welding techniques, such as TIG (Tungsten Inert Gas) welding, are essential for creating strong, leak-proof joints in stainless steel pipework. Skilled welders ensure that each joint meets stringent quality standards.

-

Prefabrication: To enhance efficiency and accuracy, many installations involve prefabricating sections of pipework offsite. This approach minimizes disruption on-site and ensures a higher level of precision in the final installation.

-

CNC Machining: Computer Numerical Control (CNC) machining allows for the precise cutting and shaping of stainless steel components. This technology ensures that each piece fits perfectly within the overall system.

-

Hydrostatic Testing: Once installed, stainless pipework undergoes rigorous testing to ensure its integrity. Hydrostatic testing involves filling the system with water and pressurizing it to check for leaks and weaknesses.

Challenges in Stainless Pipework Installations

While stainless steel offers many benefits, its installation is not without challenges. These include:

-

Material Handling: Stainless steel is heavier and harder than many other materials, requiring specialized handling and installation equipment to prevent damage.

-

Thermal Expansion: Stainless steel expands and contracts with temperature changes. Proper allowance for thermal expansion is crucial to prevent stress and potential failure in the pipework system.

-

Surface Contamination: During installation, care must be taken to avoid contamination of the stainless steel surface, which could lead to corrosion. This requires stringent handling procedures and clean working environments.

The Future of Stainless Pipework in London

As London continues to grow and evolve, the demand for high-quality stainless pipework installations is set to increase. Innovations in materials science and installation techniques will further enhance the efficiency and reliability of these systems. Additionally, the push towards sustainable and energy-efficient building practices will drive the adoption of stainless steel pipework, given its long lifespan and recyclability.

Conclusion

Stainless pipework installations are a cornerstone of London’s infrastructure, providing reliable and hygienic solutions across a range of industries. Mastering these installations requires a combination of technical expertise, advanced technology, and meticulous attention to detail. As the city looks to the future, the continued evolution of stainless pipework will play a crucial role in supporting London's dynamic and diverse landscape.

From healthcare facilities to cutting-edge architectural projects, stainless steel pipework ensures that London remains at the forefront of innovation and excellence. By embracing seamless solutions and continually advancing installation practices, the city can look forward to a resilient and sustainable future. For specialist advice and a no-obligation quotation, call IME on 02085996570 or email sales@imegroup.co.uk.