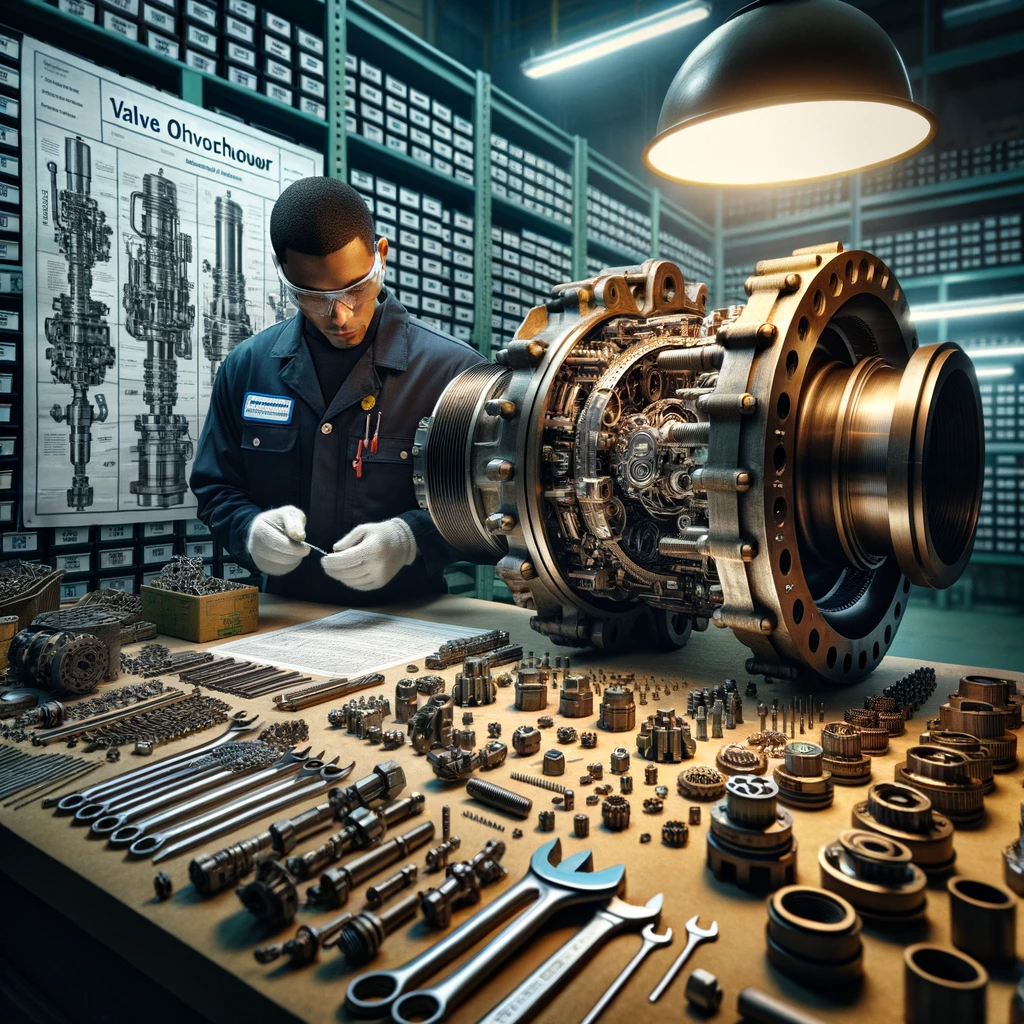

The Valve Overhaul Process: Step-by-Step

Introduction

Valves are critical components in various industries, including oil and gas, petrochemical, power generation, and more. They regulate the flow of fluids and gases, ensuring the safe and efficient operation of systems. Over time, valves can degrade and develop issues that impact their performance and reliability. That's where valve overhaul comes into play. In this blog, we'll explore the step-by-step process of overhauling valves to extend their lifespan and maintain optimal functionality.

Step 1: Inspection and Assessment

The first step in any valve overhaul process is a thorough inspection and assessment. This involves:

- Visual Inspection: Examine the valve for external damage, corrosion, or any visible issues. Inspect the valve's body, bonnet, stem, and other components.

- Functional Testing: Test the valve's operation to identify any irregularities in opening, closing, or throttling. This can be done manually or with the help of automation.

- Documentation: Record all relevant data, including the valve's serial number, type, and current condition. This information will be crucial throughout the overhaul process.

Step 2: Disassembly

Once the initial inspection is complete and any issues are identified, the valve must be disassembled for a more in-depth examination. The disassembly process involves:

- Isolation: Isolate the valve from the pipeline or system it's a part of to ensure safety and prevent any unintended fluid or gas release.

- Removal of Actuators: If the valve has an actuator (e.g., electric, pneumatic, hydraulic), disconnect and remove it.

- Dismantling: Carefully dismantle the valve, taking care to preserve all components. This includes removing the body, bonnet, stem, disc, seats, and other parts.

Step 3: Cleaning and Inspection

Once the valve is disassembled, it's crucial to clean and inspect all components thoroughly:

- Cleaning: Remove dirt, scale, and any residual fluids or gases from the valve's components. This can be done through various methods, such as ultrasonic cleaning, chemical cleaning, or abrasive blasting.

- NDE (Non-Destructive Examination): Perform NDE techniques like ultrasonic testing or magnetic particle inspection to identify hidden defects or cracks in the valve's critical parts.

- Component Replacement: Identify and replace any worn-out or damaged components, such as seals, gaskets, or valve seats.

Step 4: Reassembly and Testing

After cleaning and necessary component replacement, it's time to reassemble the valve:

- Lubrication: Apply the appropriate lubrication to ensure smooth movement of components.

- Reassembly: Put the valve components back together carefully, ensuring that all parts are properly aligned and tightened to the manufacturer's specifications.

- Functional Testing: Conduct functional tests to verify that the valve operates correctly, with no leaks or irregularities in its performance.

Step 5: Painting and Coating

To protect the valve from corrosion and environmental factors, it's advisable to apply paint or coatings, as appropriate. The type of coating will depend on the valve's material and intended use.

Step 6: Final Inspection and Documentation

Before returning the valve to service, perform a final inspection to verify that all overhaul steps were completed successfully:

- Visual Inspection: Examine the valve one last time for any cosmetic issues or discrepancies.

- Functional Testing: Confirm that the valve functions as expected and meets the required performance standards.

- Documentation: Update the valve's documentation with the overhaul details, including any replacement parts, inspection results, and testing records.

Step 7: Reinstallation and Commissioning

Once the valve has passed all inspections and tests, it can be reinstalled into the system. This process involves:

- Proper Reinstallation: Ensure the valve is correctly reconnected to the pipeline or system.

- Commissioning: Verify the valve's performance in its operational environment and make any necessary adjustments to ensure it functions as intended.

Conclusion

Valve overhaul is a meticulous process that is essential for maintaining the reliability and safety of industrial systems. By following these step-by-step guidelines, professionals can extend the lifespan of valves, prevent unexpected failures, and ensure the efficient operation of critical processes. Regular maintenance and periodic overhauls are key to the long-term success of any industrial facility.

For specialist advice and a no-obligation quotation for your valve overhaul, please call IME on 02085996570 or email sales@imegroup.co.uk.