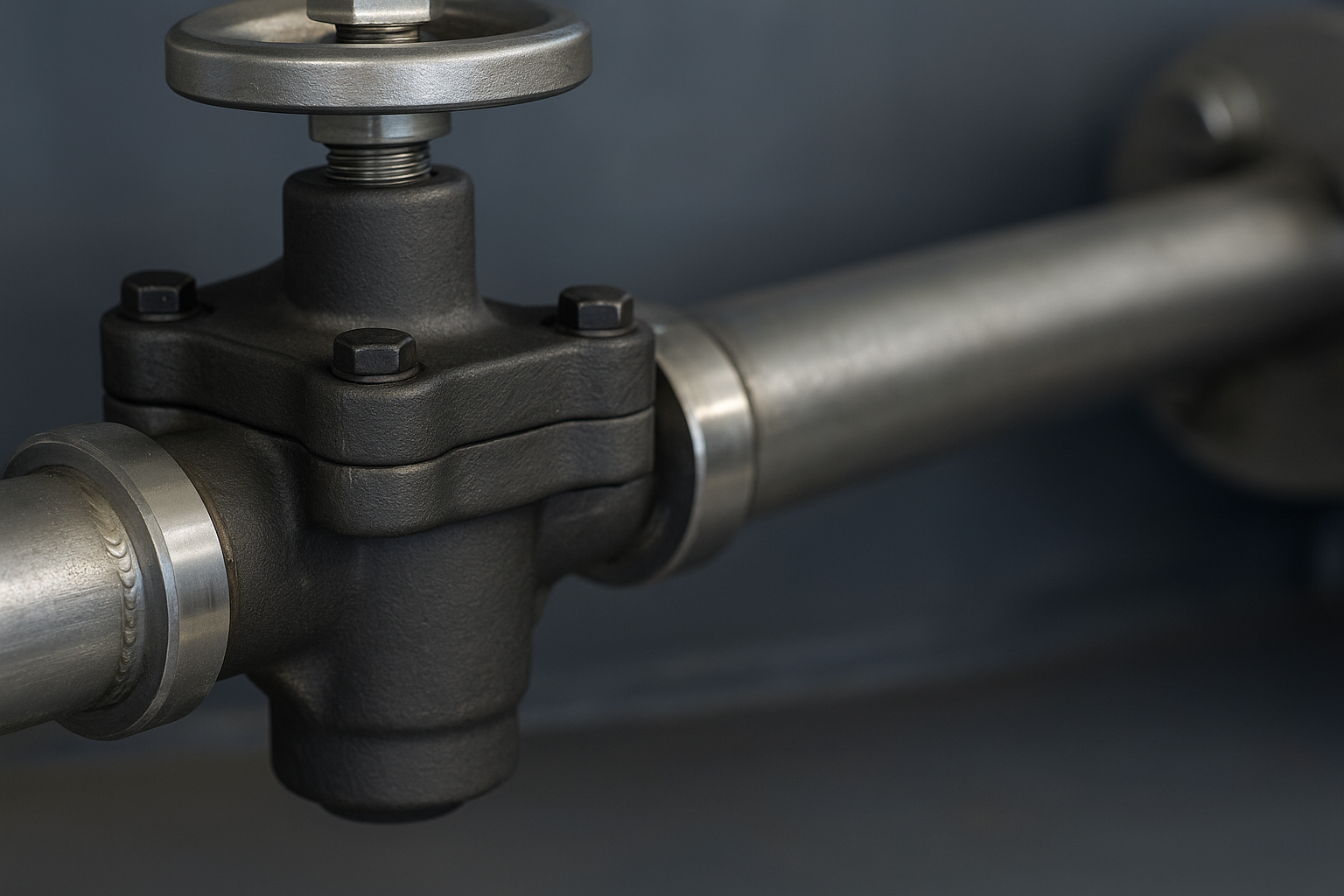

Socket Weld Valves: High-Pressure Pipework Installations

When it comes to building safe and reliable high-pressure pipework systems, the choice of valve connection is just as important as the valve itself. One option widely used in the oil and gas, chemical, and power generation industries is the socket weld valve. Designed for durability and leak resistance, socket weld valves offer a robust solution where threaded joints or flanged ends may not be suitable.

What is a Socket Weld Valve?

A socket weld valve features a connection type where the pipe is inserted into a recessed area (the “socket”) of the valve end. The joint is then secured with a circumferential weld around the outside of the pipe. This creates a permanent, pressure-tight connection.

Because the pipe end is not exposed to the flow inside, socket weld joints reduce turbulence and erosion compared with threaded or butt-welded fittings, making them particularly suited to small-bore, high-pressure applications.

Why Choose Socket Weld Valves for High-Pressure Installations?

-

Strength and Integrity

The welded connection is stronger than threaded joints and eliminates the risk of thread leaks under pressure. -

Compact Design

Socket weld valves are typically more compact than flanged alternatives, making them ideal for installations where space is limited. -

Leak Resistance

The weld around the outside of the pipe ensures a secure, leak-tight seal, essential in systems carrying hazardous or costly media. -

Alignment Ease

The socket design naturally aligns the pipe and valve during assembly, which simplifies installation compared with butt welding.

Typical Applications

In the UK, socket weld valves are commonly found in:

-

Petrochemical plants handling high-pressure steam and hydrocarbons

-

Power stations where integrity under thermal cycling is vital

-

Process industries using high-pressure gases and corrosive fluids

-

Hydraulic systems where compact, leak-free connections are critical

Things to Consider Before Installation

-

Pipe Size

Socket weld valves are generally recommended for small-bore pipework (DN50 / 2" and below). For larger bore systems, butt-weld or flanged valves may be more practical. -

Code and Standards

Always check the relevant standards (such as ASME B16.11 and BS EN equivalents) for compliance with UK regulations and site specifications. -

Welding Procedure

Skilled welding is essential. Poor workmanship can lead to cracks in the heat-affected zone. Ensure welders are qualified to the relevant UK codes. -

Future Maintenance

Because socket weld connections are permanent, disassembly is more complex than with flanged valves. Plan accordingly if the system requires frequent valve replacement.

Conclusion

Socket weld valves remain a trusted choice for high-pressure pipework installations where strength, compactness, and leak integrity are essential. By ensuring correct specification, professional welding, and adherence to UK standards, engineers can rely on socket weld valves to deliver long service life and dependable performance in demanding environments. For specialist advice and a no-obligation quotation, call IME on 02085996570 or email sales@imegroup.co.uk.